Farsoon has just introduced a new technology that allows for the additive fabrication of inverted conical structures and horizontal circular holes without the need for support structures. Known as the Support Reduction System (SRS), this technology is being officially launched to the global additive manufacturing market.

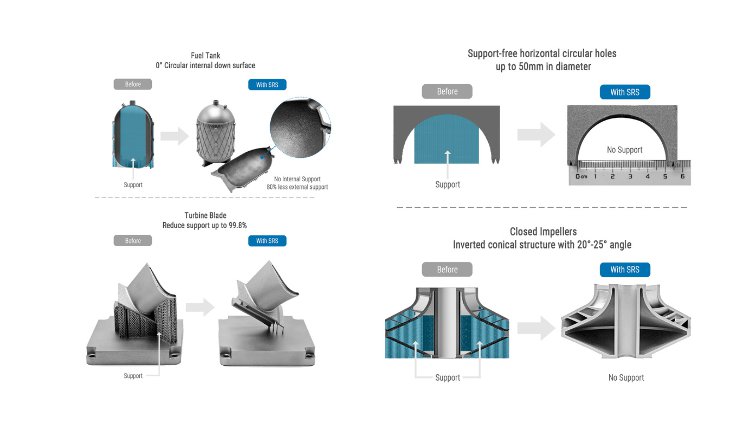

Farsoon believes that their SRS technology addresses a key challenge in additive manufacturing. Internal stresses and deformation during the cooling phase of metal powder bed fusion can often lead to part failures, particularly in overhanging structures. SRS is compatible with all Farsoon metal powder bed machines and can create inverted conical structures with a 25-degree angle and support-free horizontal circular holes up to 50mm in diameter.

According to Farsoon, SRS significantly reduces the need for support structures, which are typically required for low-hanging angles to prevent part failure. This reduction in support structures can lead to cost savings in material, printing and post-processing time, and reduce the risk of part damage. It also allows design engineers to explore more complex designs.

Using SRS, Farsoon reports that a closed impeller made with IN718 material was able to be printed 33% faster and 25% cheaper than traditional methods. SRS technology has also been applied to a variety of parts, including combustion chambers, valve bodies and nozzles, using materials like titanium alloys, aluminum alloys, and stainless steel.

This new product announcement from Farsoon follows several other new product, process and application announcements made earlier this year, including the FS721M-8-CAMS metal 3D printing solution, the Designer golf club head and the Deep Blue Aerospace combustion chamber.

/cloudfront-eu-central-1.images.arcpublishing.com/prisa/AYB5ZS7PUZHCZMYCZR33DXBJCA.jpeg)